-

Home

-

About Us

-

Products

-

Video

-

News

-

Blog

-

Contact Us

Leave Your Message

Request a Quote

The Auto Syringe is a remarkable innovation in medical technology. Its features enhance user convenience and accuracy. Understanding these features is essential for selecting the right device.

One key aspect of an Auto Syringe is its ability to limit dosage errors. This function is vital for patient safety. Moreover, adjustable speed settings cater to various applications. Ease of cleaning and maintenance is another important feature. Users often overlook this detail, leading to potential hygiene issues.

Furthermore, some Auto Syringes come with smart technology. These devices can track medication history and remind users of dosing schedules. However, not all models provide this feature. It's crucial to evaluate options carefully. While the benefits are clear, exploring personal needs and settings is necessary. Each user's experience with an Auto Syringe may vary. This diversity highlights the importance of informed decision-making.

Auto syringes have become essential in medical settings. Understanding their key design features can enhance patient safety and medication accuracy. A recent report by the Medical Device Industry Association highlights that over 30% of medication errors occur during administration. Therefore, knowing what makes a good auto syringe can make a difference.

One critical feature is the ergonomic design. This assists healthcare providers in administering medications with ease. Studies show that ergonomic tools reduce user fatigue by 40%, which in turn helps to improve accuracy. Additionally, auto syringes equipped with safety needles minimize the risk of accidental needle stick injuries, a concern in clinical practice. The average cost to treat a needle stick injury can exceed $1,000.

Tips: Ensure that the auto syringe has a clear dosage display. This can help prevent dosage errors. Also, check if the syringe offers a self-locking mechanism. This feature can enhance safety and prevent accidental injections.

Another vital aspect is the material used. High-quality plastics provide durability and ensure that syringes do not break under pressure. However, some materials may be prone to degradation over time. Therefore, it's important to assess the expiry dates regularly. An optimal cleansing mechanism can also provide better hygiene. Remember that not all auto syringes are created equal, and a thorough evaluation is necessary.

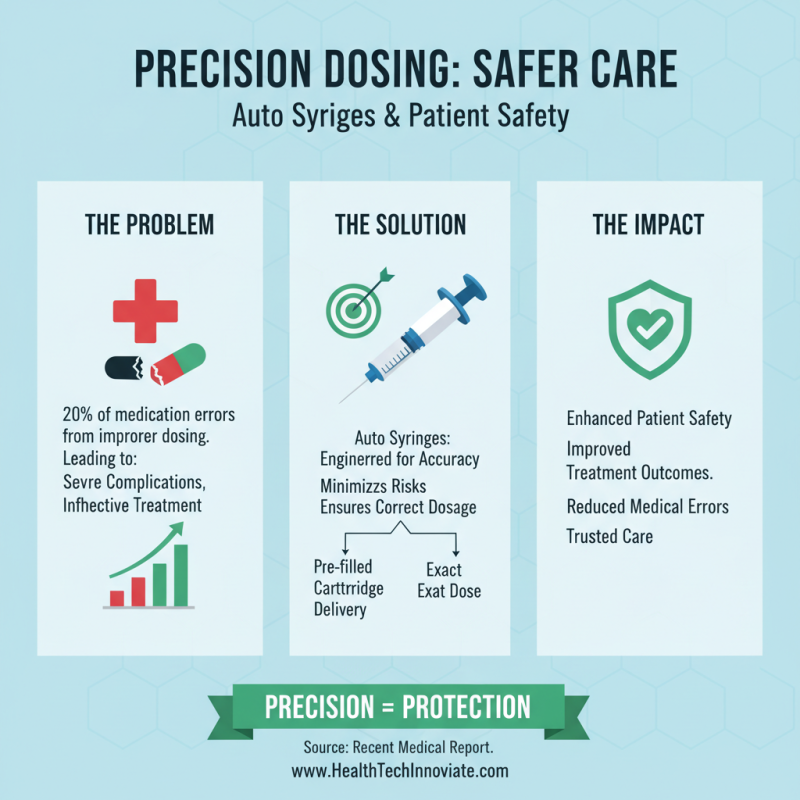

Precision dosing in auto syringes is crucial for patient safety. A recent report highlighted that improper dosing accounts for 20% of medication errors. This is alarming. These errors can lead to severe health complications or ineffective treatment. Auto syringes are designed to minimize these risks by providing accurate dosages with each use.

Tips: Always check calibration. Regularly evaluate the device to ensure it dispenses the correct amount. User training is essential. Consistent training can reduce user errors significantly. Data shows well-trained operators have a 30% lower error rate.

Patients deserve the best care. An auto syringe’s precision can radically affect treatment outcomes. When a syringe delivers either too much or too little, it compromises the treatment. Sometimes, devices malfunction. This highlights the need for regular maintenance checks. A report noted that 15% of syringes fail the accuracy tests after six months of use.

Preventable issues can arise from overlooking these details. Regular updates on procedures and training can fill these gaps. Always observe best practices to enhance safety and ensure the reliability of auto syringes.

When it comes to auto syringes, materials play a crucial role in user experience. Most auto syringes are made from plastic or glass. Plastic is lightweight but may not always offer the best durability. Glass, on the other hand, is more robust but is heavier and more fragile. This choice affects how comfortable the syringe feels in hand. Users often prefer a balance between lightness and sturdiness.

Ergonomics is another critical aspect. The design should allow for a natural grip. Contours that fit the hand can reduce strain during use. A syringe that is easy to handle makes a significant difference, especially during repetitive tasks. Some designs include rubber grips, which can enhance comfort but may wear out over time. Reflecting on these factors is essential; what feels good initially might become uncomfortable with extended use.

Durability of materials also raises questions. For instance, how do different plastics hold up under pressure? Are they prone to cracking? These issues can affect long-term use. Additionally, some users report that the aesthetics of a syringe matter. A visually appealing design can make a user more inclined to use it. However, beauty should not compromise functionality. Balancing aesthetics and practicality remains a challenge for developers.

Smart auto syringes are becoming essential in healthcare. They integrate technology to enhance patient care. These devices have features like automatic dose calculations. They can reduce human error significantly. Many syringes connect to mobile apps for easier tracking. This helps patients manage their medication schedules more effectively.

Connected health solutions are also evolving rapidly. Auto syringes can send data to healthcare providers. This allows for real-time monitoring of patient adherence. However, not all users find these technologies intuitive. Some may struggle with setup or connectivity issues. It's essential that manufacturers consider user experience carefully.

As we embrace these advancements, there’s a need for user education. Patients may not understand how to use these tools. Training and support are crucial for maximizing benefits. While smart syringes offer great potential, they must be user-friendly. Otherwise, the technology risks being underutilized, leaving room for improvement.

Regulatory standards play a crucial role in the auto syringe manufacturing industry. Compliance is not just a box to check; it is essential for patient safety. The ISO 13485 standard ensures quality management systems address the requirements of medical device manufacturing. This compliance can reduce risks associated with product failure. According to a recent industry report, 40% of medical device recalls are due to non-compliance issues.

Manufacturers must also adhere to FDA guidelines. These include robust testing and documentation procedures before a product enters the market. A staggering 70% of auto syringe manufacturers reported challenges in meeting these requirements. Insufficient understanding of regulatory processes often leads to significant delays. Companies in this sector must prioritize regulatory education for their teams.

Quality assurance in production is vital. Detailed records should be kept for every batch produced. Inadequate or irregular record-keeping can lead to serious repercussions. Furthermore, many manufacturers struggle with integrating new technologies while complying with existing regulations. This ongoing challenge requires regular audit assessments and a culture of transparency within organizations. Consistency in compliance contributes to long-term success in the industry.