COMPETITIVE ADVANTAGES

Never Miss a Dose

Eliminates spring failure during large-scale operations

Farm-Tough

Survives muddy boots, chemical spills, and rough handling

Save Time & Money

Reduce syringe replacement costs by 40% with durable springs

Easy to Use

Replace springs in 30 seconds, no technical skills needed

Trusted by Pros

Adopted by veterinary networks and industrial poultry farms worldwide

Leave Your Message

DETAIL CHART

Application

Vaccination Drives: Maintain steady pressure for rapid vaccine delivery in herd immunization programs.

Antibiotic Administration: Prevent dosage errors caused by spring fatigue during prolonged use.

Hormone Injection: Ensure smooth piston retraction for oil-based formulations in breeding management.

Field Repairs: Swap worn springs in seconds without tools, keeping syringes operational during critical tasks.

Hygienic Operations: Withstand daily sterilization (alcohol/autoclave) without losing elasticity.

Material

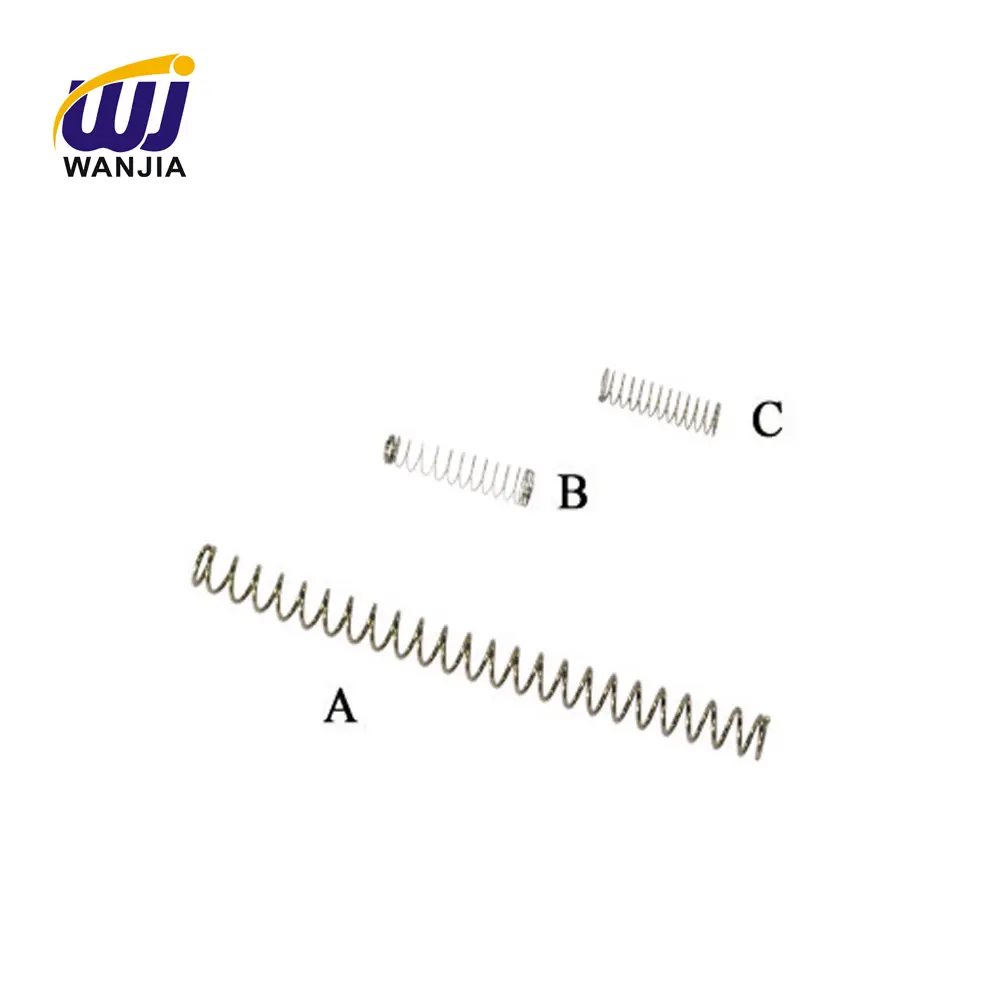

A: Main Spring | B: Nozzle Spring | C: Imbibition Spring

Features

Precision Tension Control: Each spring type (A/B/C) optimized for specific syringe functions:

Fatigue Resistance: Retains 95% initial tension after 50,000 cycles

Universal Fit: Compatible with 10ml-50ml syringes across brands

Low Maintenance: No lubrication required, resistant to vaccine residues and organic matter

Cost-Effective: 3x lifespan compared to standard stainless steel springs